Tailings management

Tailings are the sand, silt, clay, water and residual bitumen left over after mining and bitumen extraction. Efficient management of tailings is key to reducing the environmental impact of oil sands operations.

Tailings Aspirations

We aspire to transform tailings from waste into a resource that speeds land and water reclamation.

Achieving this goal will involve developing new and improved tailings technologies. The Tailings EPA is working closely with industry and innovators to advance innovative and sustainable approaches.

Tailings research annual report

November 2022

Catch up on some of the highlights of our recent progress in tailings management.

Tailings Priorities

Significant gains have been made in tailings technologies. The work involves close collaboration with universities, government, research institutes, and others.

Reduce environmental impact of tailings

Mitigate the accumulation of fluid tailings

Accelerate tailings recovery and land reclamation

What we’re doing

Lab research and field testing supported by COSIA are advancing tailings technologies in several areas.

Reducing tailings volumes

Processes that reduce the amount of tailings left over after bitumen extraction put us one step ahead of the game. Creating fewer tailings benefits all aspects of tailings management.

Reclaim tailings faster

We’re testing new technologies that can reduce the amount of water in tailings before they are used in reclamation. Less water means tailings can be reclaimed faster.

Creating new industry standards

We’re supporting work to develop a better way to measure tailings consolidation. This work addresses a significant gap in how industry understands tailings management and will help improve environmental performance.

Research funding

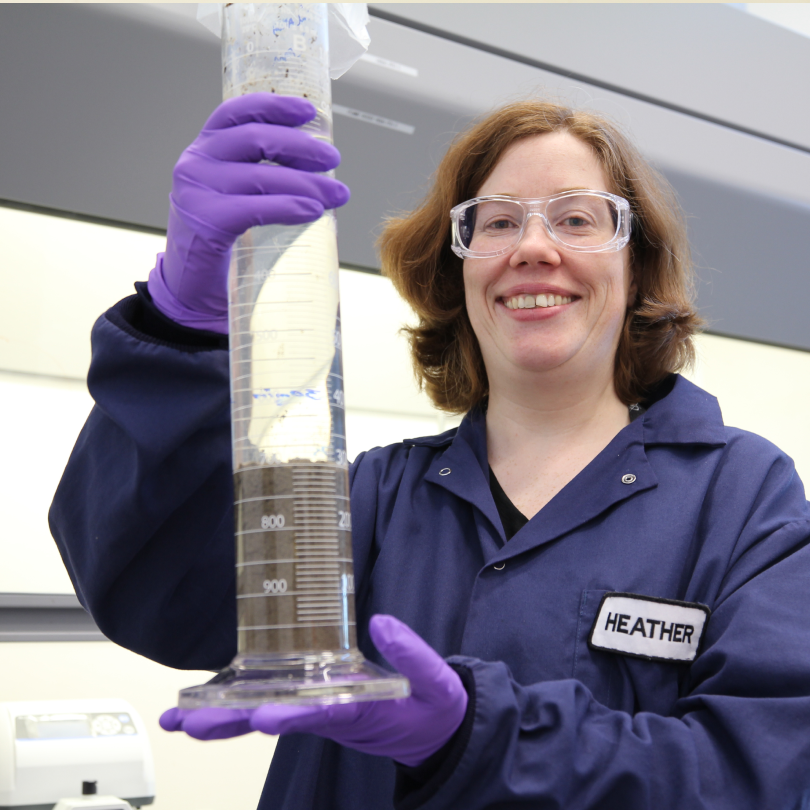

COSIA funds research programs at Carleton University, NAIT and the University of Alberta that help address important aspects of tailings management.

Tailings innovation opportunities

We want to hear from anyone with an idea—academics, researchers, inventors, entrepreneurs—that can help us improve tailings management. Explore the current innovation opportunities to see where you can contribute.

| Challenge | Tags | Details | |

|---|---|---|---|

| Capping of Tailings Deposits | Tailings |

Refine existing methods and best practices and develop novel techniques for stabilization, capping, and reclamation of tailings deposits including CT/NST, thick fines-dominated deposits (TT, Centrifuge cake, polymer-treated FFT). |

Download Challenge Brief |

| Clay Chemistry Impacts on Permeability and Consolidation of Fines-Dominated Deposits | Tailings |

Improved understanding of the effects of clay types on permeability and consolidation of polymer-treated fine tailings, resulting in improved prediction of tailings processes, deposit modelling and adaptive management of tailings deposits. |

Download Challenge Brief |

Tailings: featured content

Read more about our efforts to improve tailings management.